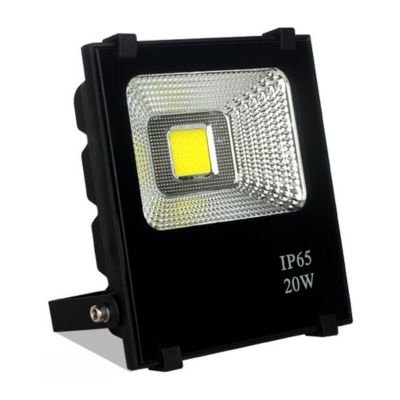

Are you a property manager responsible for purchasing or maintaining lighting systems for a warehouse, parking lot, factory, or commercial complex? Or are you an architectural lighting designer or an LED lighting retailer?

This post will introduce the differences between COB (Chip-on-Board) and SMD (Surface-Mount Device) flood lighting, focusing on their techniques, costs, and installation processes.

Table of Contents

What is COB? & What is SMD?

SMD(Surface-Mount Device)

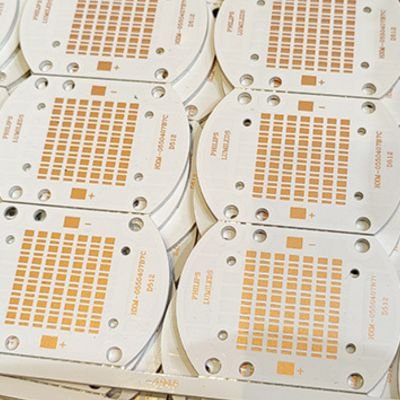

SMD is the single LED beads, such as 2835, 3030, and 5050 chips, which are welded on aluminum PCBs. It is formed by connecting individual encapsulated LED chips in specific series and parallel configurations through surface-mount soldering technology to create a large light-emitting body.

The wattage or lumens of a light source depends on the number of individual LEDs.

COB (Chip-on-Board)

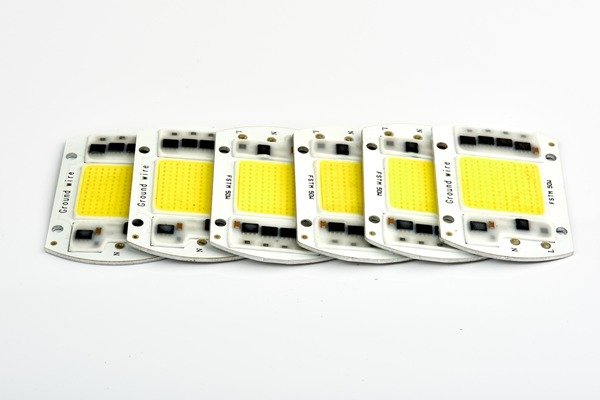

COB technology employs semiconductor packaging processes to integrate multiple LED chips and pre-package them onto a substrate.

Generally, COB light sources have relatively fixed dimensions and wattages: 10W, 20W, 30W, 50W, 80W, 100W.

What is the difference between COB and SMD LED flood lights?

COB technology was developed to deliver high power or lumen output from a compact light-emitting surface.

However, SMD technology has not been rendered obsolete by the emergence of COB technology, particularly in the flood lighting sector.

In fact, both technologies have carved out distinct paths in their respective application domains.

Below is a detailed comparison table of COB and SMD flood lights:

| ITEM | COB FLood Lights | SMD Flood Lights |

|---|---|---|

| LED Structure | Single large chip (Chip On Board) with larger light-emitting area | Multiple small chips packaged side-by-side |

| Luminous Flux Density | High light density, stronger brightness per unit area | Even light density distribution but lower single-point brightness |

| Illumination Uniformity | Concentrated illuminance with strong edge transitions | More evenly distributed light, fewer shadows |

| CRI | 70-80 | 70-90+ |

| Thermal Management | Requires efficient heat dissipation design to prevent power degradation | Lower individual chip heat, easier overall thermal management |

| Drive Current Requirement | Normal | Normal |

| Energy Efficiency (lm/W) | <90 | 80-110 |

| Form Factor & Design | Compact design with concentrated light source area | Wider chip distribution enables thinner, lighter designs |

| Cost (for equivalent brightness) | Potentially higher cost at equal luminous flux | Mid-to-low power solutions often offer better value |

| Glare Resistance | High-density light spots require dedicated anti-glare design | Distributed light spots help reduce glare |

| Suitable Scenarios | Requires ultra-high brightness and long-distance projection (large venues, stadiums) | Uniform illumination for medium to large areas (parking lots, building facades, courtyards) |

| Color Temperature | 3000K-6500K | Any light color can be customized. |

| Dimming/Light Control Compatibility | Better compatibility with linear driver dimming | Supports multiple dimming solutions like PWM/triac |

| Reliability | Single-chip overheating may affect overall performance | Multi-chip designs offer better fault tolerance and minimal impact from localized failures |

| Price Range (General) | Predominantly mid-to-high-end market | Widely covers mid-low to high-end segments |

How Do I Choose Between COB and SMD Flood Lights?

Previously, it was believed that COB, due to its smaller light-emitting surface, could produce more concentrated light beams and thus achieve longer illumination distances compared to SMD.

In reality, LED technology has made significant strides. COB can now also be manufactured with larger light-emitting areas, as shown in the figure below.

High-brightness 3030 and 2835 single-chip LEDs, capable of delivering 1-3W of power, can now replace COB chips for concentrated mounting and serve as substitutes for COB light sources.

Through mutual integration and adaptation, the differences outlined above have become negligible, and neither technology can fully replace the other.

FAQs

SMD flood lights deliver higher luminous efficacy than COB flood lights because SMD technology allows for a larger surface area to accommodate more LED chips, resulting in a 25%-50% increase in overall luminous efficacy.

COB is not superior to SMD. SMD LED floodlights offer a wider selection of LED chip brands, so the current development of SMD floodlights is more advanced than that of COB.

SMD is superior. Unlike COB, which relies solely on aluminum reflectors to adjust beam angles, SMD flood lighting offers a wider range of lens options. Each individual LED can be assigned its own dedicated lens, enabling more precise light distribution.

SMD floodlights are easier to maintain because even if a single LED fails, it can be replaced individually, whereas COB requires replacing the entire light source.

SMD flood lights offer a wide variety of styles across both low-end and high-end products, resulting in a more extensive product range. Consequently, the actual procurement cost should be lower.